how is copper ore mining crushing

مجال التطبيق

خط إنتاج معالجة البوكسيت 200TPH في غينيا

تم الإشادة بنظام التحكم الذكي Liming Heavy Industry. تمكننا من مراقبة خط الإنتاج المحلي في الوقت الفعلي ومعرفة معلومات الموقع في الوقت المناسب ، مما يوفر راحة كبيرة لإدارتنا.

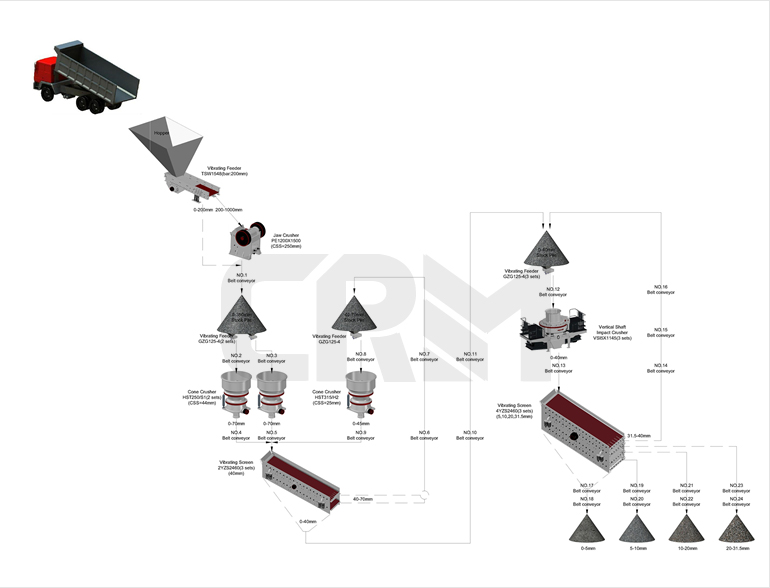

المعدات: كسارة فكية PE750x1060 ، كسارة مخروطية هيدروليكية HPT300

المواد: البوكسيت

السعة: 200 طن / ساعة

حجم المدخلات: 600 مم

حجم الإخراج: 0-20mm.

التطبيق: إنتاج سبائك الألومنيوم ، التصنيع الحراري

How Do You Mine Copper Ore: A Guide to the Extraction Process

2023年9月26日 Utilizing Modern Technologies In Copper Ore Mining; Crushing And Grinding: The Initial Steps In Ore Processing; Differentiating Between Sulfide And Oxide Ores In Copper Extraction; Applying Flotation Techniques To Separate Copper From Other Minerals; Concentration And Smelting: Turning Copper Ore Into Usable Metal. FAQs;

Copper Mining and Processing: Everything you Need to

2014年7月17日 Mined from open pits, copper ore must be crushed as part of the process that occurs between extraction and production. Using today’s compact mining equipment, copper ore is extracted from the mine. After the ore is crushed, it’s roasted, which helps to convert sulfides to oxides.

What is the process of crushing copper ore? - LinkedIn

2023年3月16日 Here is a general outline of the process: Mining: Copper ore is typically mined from an open-pit mine or underground mine. The ore is then transported to a... Crushing: The ore is crushed into smaller pieces that are less than 25 centimeters in diameter. This is usually done... Grinding: The crushed ...

How is Copper Ore Processed - 911 Metallurgist

2016年11月20日 PRIMARY CRUSHING —The ore is hoisted from the two shafts in nominal 10-ton capacity skips and discharged into 1000-ton

Mineral processing Metallurgy, Crushing Grinding

mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a

The Role of Crushing in the Copper Mining Process

The copper ore is first crushed to a coarse size using jaw crushers and cone crushers. This reduces the ore’s volume and prepares it for further processing. The crushed ore is then passed through a series of grinding mills, such as ball mills and rod mills, which further reduce the particle size.

Copper processing - Ores, Refining, Smelting Britannica

In the ore-dressing plant, the material received from the mine is crushed in several stages and finely ground to a size which ensures that copper minerals are liberated from the waste materials, or gangue.

How to Process Copper Ore: Beneficiation Methods and

2023年3月13日 Copper ore beneficiation methods Before the beneficiation of copper ores, crushing and grinding are required. The bulk ores are crushed to about 12cm by a jaw crusher or a cone crusher. Then the

Optimizing the Rougher Flotation Process of Copper Ore

2019年2月22日 This paper focuses on optimizing the parameters of the copper ore flotation process, which is the most expensive in obtaining copper concentrate, in order to improve the copper grade, corresponding to the fine copper law in the copper concentrate and metallurgical recovery, in order to obtain more final tons of fine copper, in the ...

2-12-24SERVICE MECHANISM

Common choice of more than 170 countries

Email:[email protected]

المحادثة على الإنترنت

المحادثة على الإنترنت